Did you not find what you were looking for?

EPEX is a patented technology and the flagship membrane technology of Elvstrøm Sails.

The EPEX technology enables one workflow from design to the finished membrane sail, all at our loft in Denmark close to the market. The EPEX table is the most accurate in the world and the biggest of its kind.

The patented application head places every single yarn precisely on the right spot while the intense vacuum holds the entire membrane in place. This ensures that any material shrinkage during the curing process is eliminated.

The world’s most advanced vacuum table uses over 500.000 vacuum nozzles across the entire laminating surface. Through these nozzles we apply a constant negative air pressure which draws out all air bubbles, holds the blade in place and compresses the membrane layers.

During the lamination process two things are crucial. First of all, to eliminate trapped air and secondly to apply a constant temperature to prevent the blade from local shrinkage. The EPEX technology meets both challenges.

Heaters & sensors ensure a constant temperature across the entire blade during lamination. The extreme pressure by vacuum ensures that the air around the yarn built-up is eliminated. The result is a strong and solid membrane with no air pockets and/or crushed fibers.

On some of the materials and sail types within our EPEX range of products, the batten pockets can be integrated directly into the membrane. That leaves a 100% symmetric membrane with equal profile and performance on both tacks!

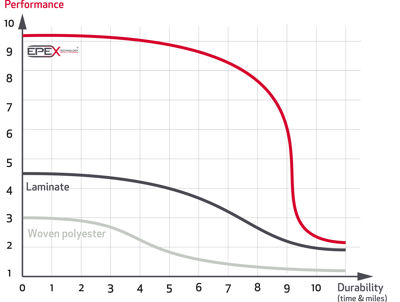

The EPEX membrane sails are extremely strong and endure even the most rigorous conditions for years and years to come.

The shape keeps up and delivers an outstanding performance.

In our 3D configurator you can try out a number of EPEX material combinations. And you can read more about the EPEX layout here.