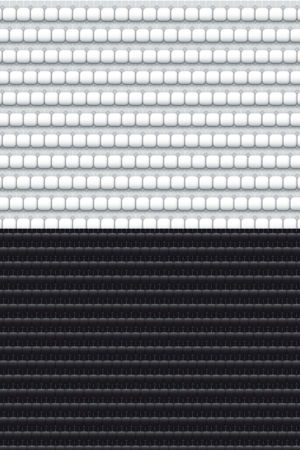

Dacron is well known in the world of sailing, and it has for decades been a great choice when it comes to unite an affordable price point with long-lasting performance.

Also known as woven polyester, but often also under its brand name of Dacron, the material brings great UV-resistance and reliability whilst maintaining a low price compared to newer, stronger and more modern material choices.

It is however important to underline that Dacron is a great sail fabric, and it still remains a very popular choice for cruisers today.

So what are sails made of? Often from Dacron. This is the material most people first think of, if you describe a regular, white sail cloth.

The history of Dacron in sailmaking

Introduced in the 1950s, Dacron was a revolution to sail design. At that time, it offered a significant improvement over traditional cotton sails, which were heavier, less durable, and prone to stretching and rotting.

One of the primary advantages of Dacron is its excellent UV resistance, which is crucial for sails that are exposed to the sun's harsh rays for extended periods. The material’s resistance to mildew and mold, combined with its minimal water absorption, makes it an ideal choice for long-term use in a marine environment.

We do however recommend that you still take care of your dacron sails, so ensure they are packed dry and that they are under cover rather than being exposed for harsh sun for extended periods.

Stretch and reliability of Dacron sail cloth

Dacron sails are known for their stretch resistance, which is critical in maintaining the sail's shape and efficiency over time. While they do stretch more than high-tech materials like laminate or composite fibers, they provide a good balance of performance and longevity, especially for cruising and recreational sailing.

This stretch resistance helps in maintaining the desired sail shape, providing consistent performance across various wind conditions.

Moreover, Dacron sails are easier to repair and maintain compared to more modern materials. Small tears or damages can often be fixed with simple stitching, making Dacron sails a cost-effective option for sailors who value practicality and ease of maintenance.

While high-performance racing sails have largely moved towards advanced materials such as carbon fiber or Technora, Dacron remains a popular choice for cruising sails and entry-level racers. Its affordability and versatility make it accessible for a wide range of sailors, from beginners to experienced cruisers.

Overall, Dacron continues to hold its place in the sailmaking industry as a reliable, durable, and cost-effective material, ideal for those who seek a balance between price and longevity.

How does Hydranet fabric compare?

Hydranet sail fabric is a later variation so to say.

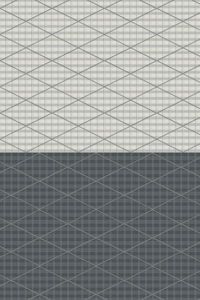

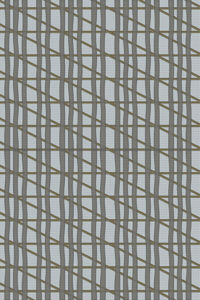

Sails are often made from fabrics and cloths where materials are combined to add strength - and to simplify this, Hydranet is in the same family as Dacron being a woven type of fabric just like Dacron. The Dacron is woven polyester fabric, where Hydranet features Ultra-High Molecular Weight Polyethylene (UHMWPE) fibers, also known as Dyneema to add strength and stretch resistance to the material.

So compared to traditional dacron sailcloth, you will see Hydranet proving better on strength and durability, but often also a little step up on the price point.

A third variation of this is called Fibercon - and again, Fibercon fabric is also in the same family of sailcloths being a woven material - just like the two others.

The steps up in terms of performance, shape retention and weight saving are laminate sails and then membrane sails such as EPEX.